Board cameras used in FPV applications can be quite vulnerable, and sooner or later, through-hole leaded components can fatigue and break off with vibrations.

One of the most fragile components is the crystal.

(Standard designator for a crystal is ‘Y’)

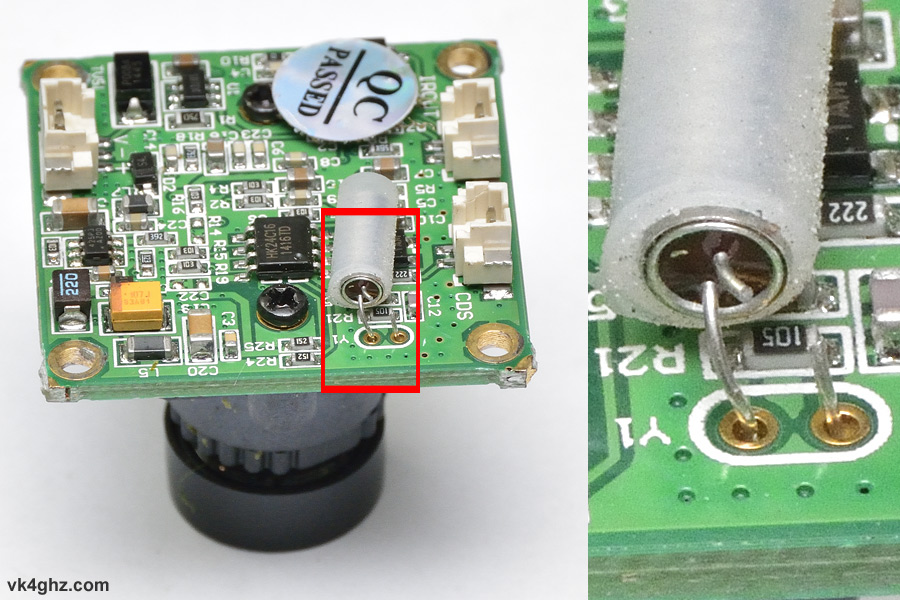

This crystal, with one broken leg, will be moved to the other side of the PCB:

Move the broken off leg to the other side of the PCB.

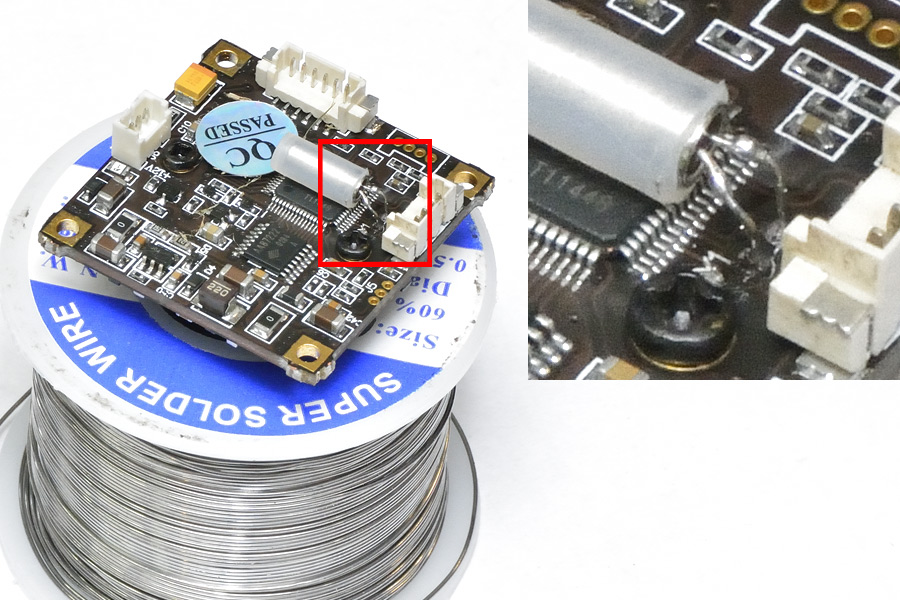

I find it’s much easier to work with these cameras, if you sit them on the reel of solder:

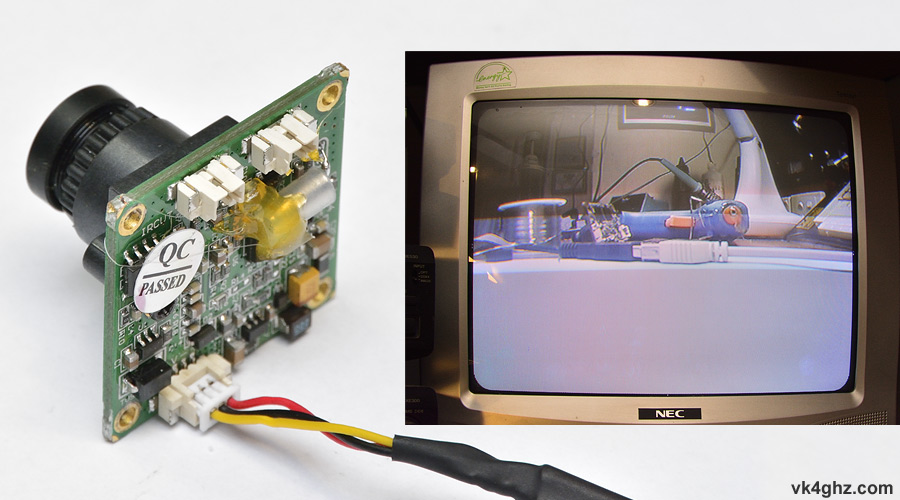

When both legs have been soldered, test by hooking up power and the video out to a monitor:

Once that checks out, we need to stop the crystal from flopping around again with vibrations.

Easiest way to do this is to hot-melt glue the crystal body down to the IC package:

Re-test before fitting back into your model.

🙂

Camera #2

This particular board camera already has the crystal mounted on the “other” side, but one of the leads has broken anyway:

Broken lead has been re-soldered:

Once again, the crystal is held down in place with hot-melt glue:

This should stop the relatively large body from moving around, and ultimately fatiguing a leg:

Re-test before fitting back into your model.

🙂