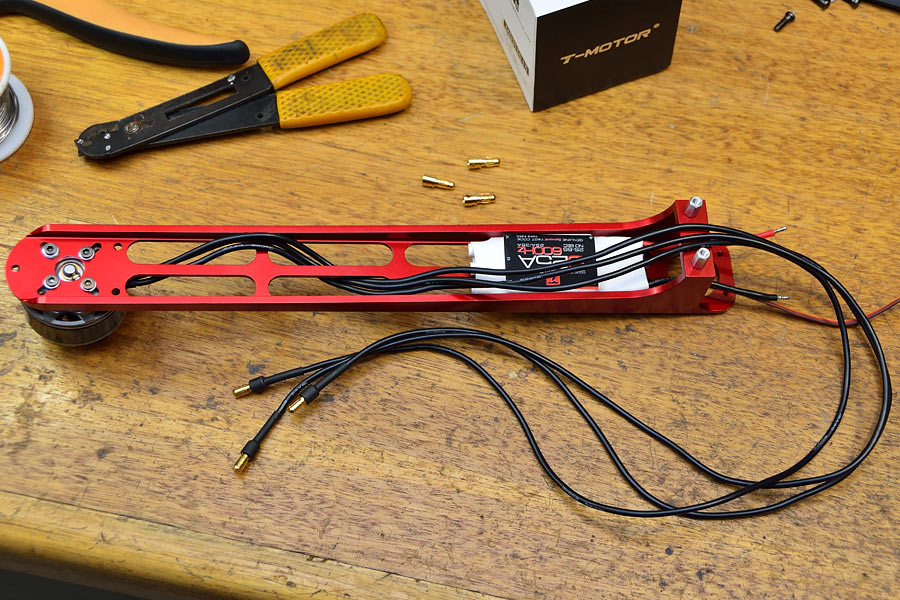

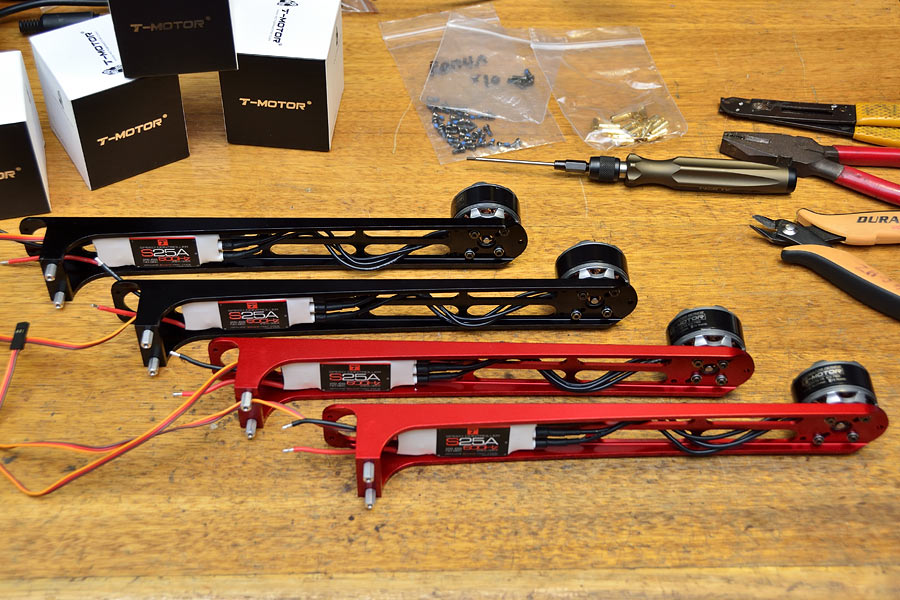

After playing around with layouts, it was time to actually start mounting motors and ESCs for real.

Key components:

• Aimdroix extended aluminium arms

• T-Motor MN3110-15 780kV motors

• T-Motor S25A ESCs

• 4mm bullet connectors

MN3110 motor wires come 600mm long, which is a lot of dead weight if just cable tied up, so the wires are to be trimmed back.

Above: Unless heatshrink is 4:1 shrink ratio, you will most likely need two sizes to cover the wire and connector body

Above: Often easier if a connector like this “sits” in between plier jaws, to prevent them wobbling around all over the bench

Above: two layers of standard 2:1 heatshrink finishes a termination off nicely

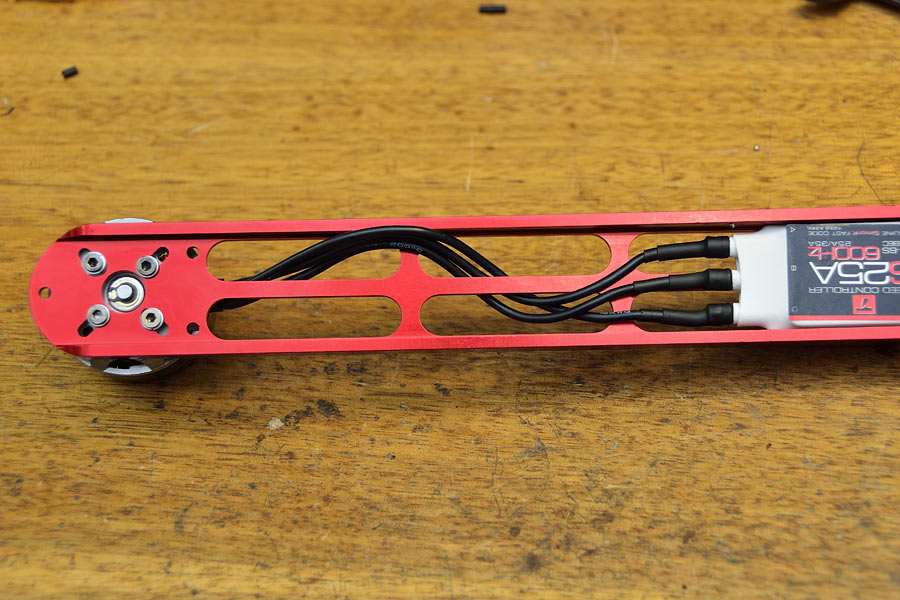

Above: motor wires weave in between arm structure – no need for cable ties here

Above: motor bolts to frame with M3 hardware

As well as blue Loctite on the screw, spring washers are also being used.

Unlike the stock plastic arms, these aluminium arms will become a heat sink to help dissipate any motor heat, should that ever become an issue. Motors shouldn’t become “hot” in well designed system, however.

Above: T-Motor motor wiring is 18AWG and outer sheath is rated at 200° Celsius.

There were absolutely no issues with the outer sheath shrivelling back up with the heat from soldering, as often found with cheap and nasty wire.

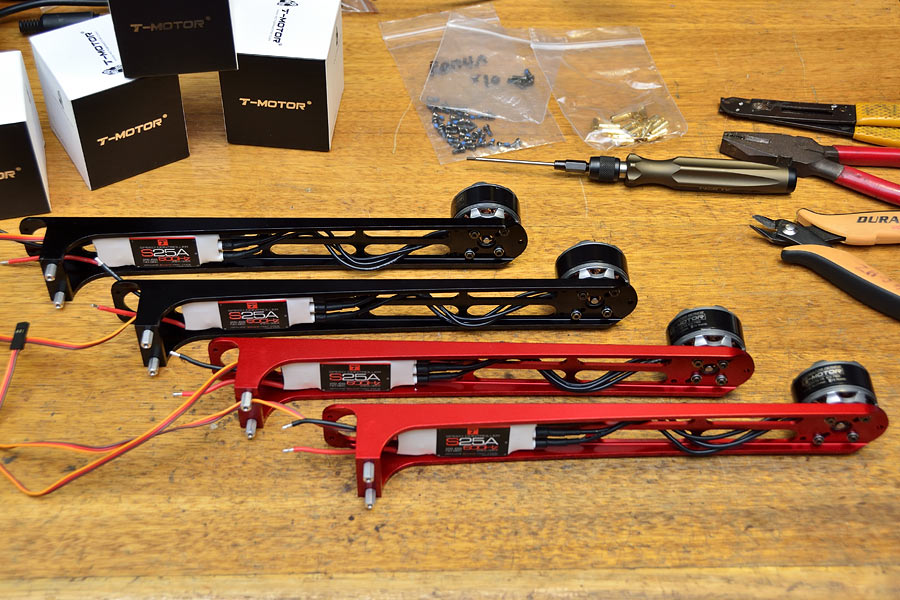

With one arm done, only three more to go!

Above: ESCs are a nice tight fit within the arms

So how much weight was saved by trimming the motor leads?

Above: 57grams saved – gotta be happy with that! 🙂

Reclaimed 4mm bullet connectors can always be used elsewhere.

Next job: Soldering ESC leads to F450 lower board, and mounting the Wookong-M flight control components and receiver.