This takes a look at the Titan Y6 frame kit from Fortis Airframes in the USA.

In addition to the frame itself, a number of accessories were also purchased;

• Large camera mount

• Video transmitter mast

• An additional electronics cover

• Being weird American threads, a spare hardware kit

Described as ;

The TITAN Y6 is designed to carry payloads up to 1.5kg (including batteries), which will allow you to lift compact mirrorless cameras such as the SONY NEX series.

By far the least expensive way to get a high-quality camera in the air, it is the ideal compact, quick-deploying platform for aerial photography.

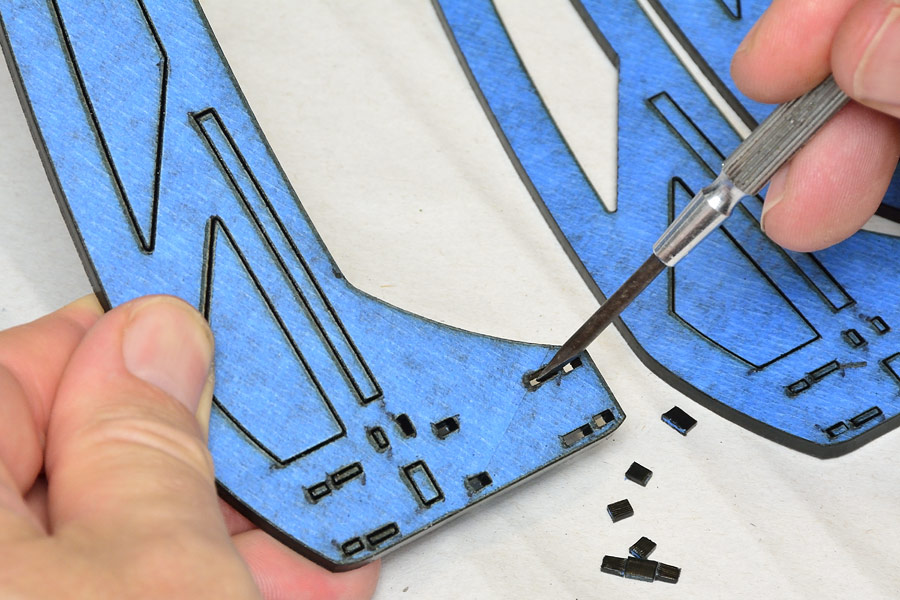

Components of the TITAN frame are made from 3.1mm (1/8″) laser cut “Delrin”, a thermoplastic from the Polyoxymethylene family.

Stronger than most injection molded plastics yet more flexible than aluminum or carbon fiber

You can learn more about Delrin on WikiPedia.

A key feature (and point of difference) with this frame are the “break away” components.

Motor mounts, legs, GPS and video TX masts are clamped the booms using standard mini cable ties that have a tensile strength of 18 lbs (80N). Such as these Nylon 66 cable ties from RS.

The idea is, parts will break off, rather than break in the event of a crash.

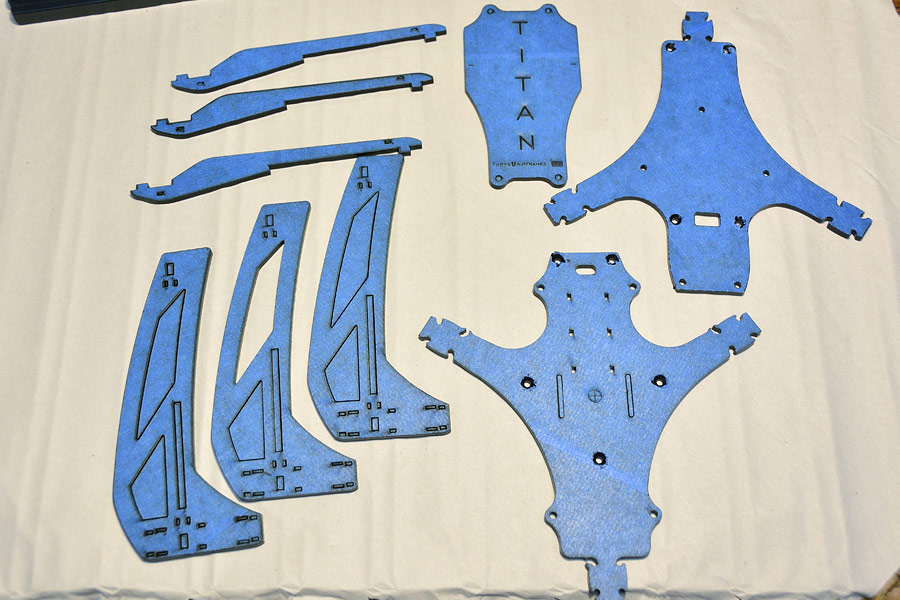

So what’s in the kit?

16″ carbon fibre booms were ordered and these will accommodate props up to 11″.

(13″ booms are also available, and will take up to 8″ props.)

The laser-cut Delrin pieces come with the masking tape still on.

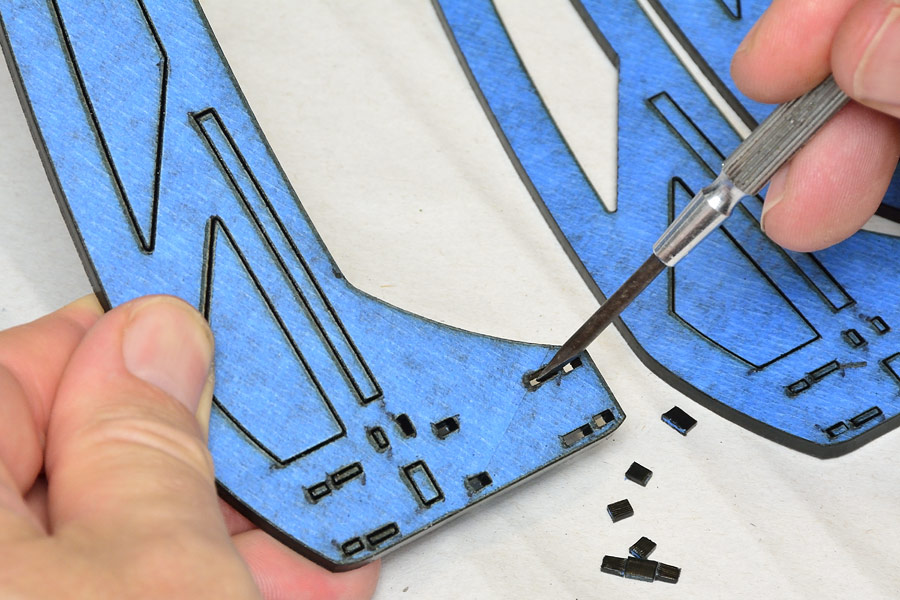

First job is to punch out the material from the cutouts. A small flat-blade screw driver was used:

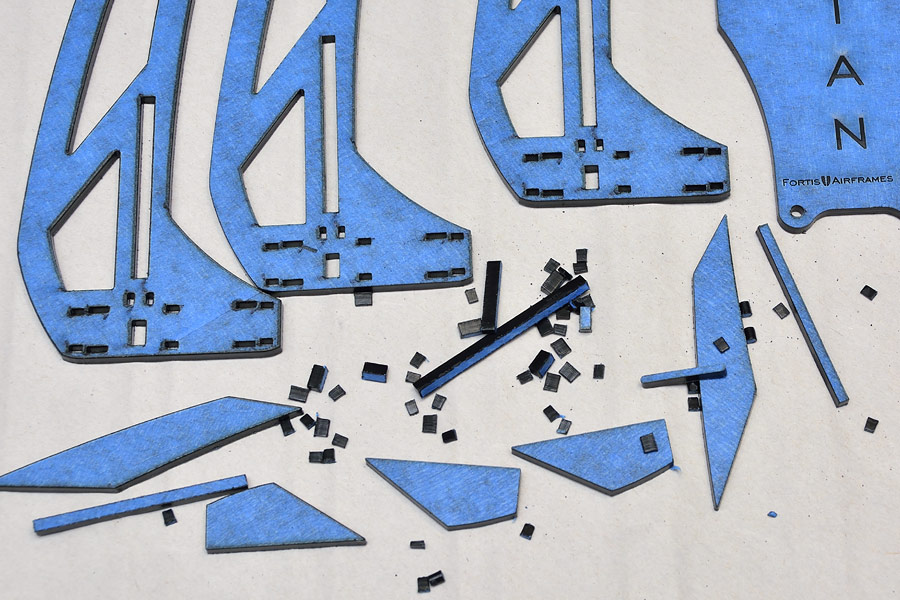

Masking tape is peeled off:

IPA (Isopropyl Alcohol) was used with a rag to wipe away any adhesive residue:

Laser cutting and etching is well defined:

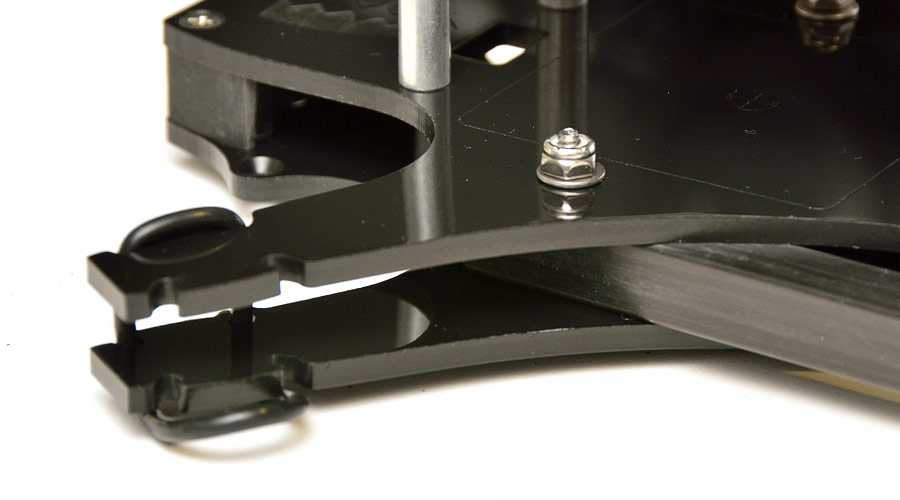

Fast forward… the frame is assembled (unattached legs in the background), and note how the booms are attached:

One bolt (with washer and lock-nut) and a rubber o-ring retainer:

This makes it incredibly easy to fold the arms for transportation, and three spare rubber arm retainers are included as standard.

These are the coaxial motor mounts, along with the laser-cut silicone motor mount pads:

What does the basic frame itself (including legs and motor mounts) weigh?

Zach has posted some video of the Titan Y6 on YouTube (note the payload – two batteries and a Sony NEX5 mirrorless camera):

I’ve found that it can take some days to get an email reply, but a posting a query on their Facebook page can get a much quicker response!

Zach suggests the following configuration:

Motors: SunnySky x2212 980kv II

Props: Turnigy 11×4.7″ slow-fly

Battery: 2x Turnigy Nanotech 3000mAh 3s in parallel (so 6000mAh 3s total)

Flight controller: APM 2.6 w/ublox 6H GPSYou can run different size props on top and bottom, but it’s going to be a trial-and-error method to determine what works best.

I haven’t taken the time to experiment but hopefully I’ll be able to try some other configurations soon.

A lot of manufacturers do “2212” motors, but given T-Motor motors are in my F550 quad, I’ll stick with the brand I know and trust (albeit expensive), so some T-Motor MT2212-13 980kV’s will be ordered soon!